公司动态

Zhongtong tells you: How to scientifically grasp the thickness of stainless steel mirror polished wo

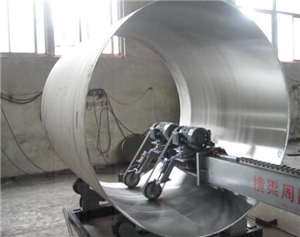

In ordinary flat polishing operations, the thickness of workpieces typically ranges from 0.3-20mm, with thicker pieces being easier to grind. The reason is that during the grinding process of a stainless steel mirror polishing machine, if the product is too thin, it often struggles to withstand the pressure from grinding. Common damages include breakage or edge collapse, and if temperature rises, deformation may even occur. However, with sufficient thickness, the likelihood of these threats is significantly reduced.

But the opposite is true for polishing stainless steel to a mirror finish. Thicker stainless steel plates are actually more difficult to polish to a mirror surface. For the same stainless steel material, thinner plates are easier to achieve a mirror finish than thicker ones. This is because beyond a certain thickness, stainless steel plates don't transmit light easily, making it difficult to achieve surface brightness. Therefore, when performing stainless steel mirror polishing, we typically choose thinner plates rather than thicker ones.

In high-precision processes like grinding and polishing, many things are not absolute nor immutable. We need to analyze specific problems during operation, avoid blindly copying set procedures, and flexibly apply the grinding knowledge we've learned.

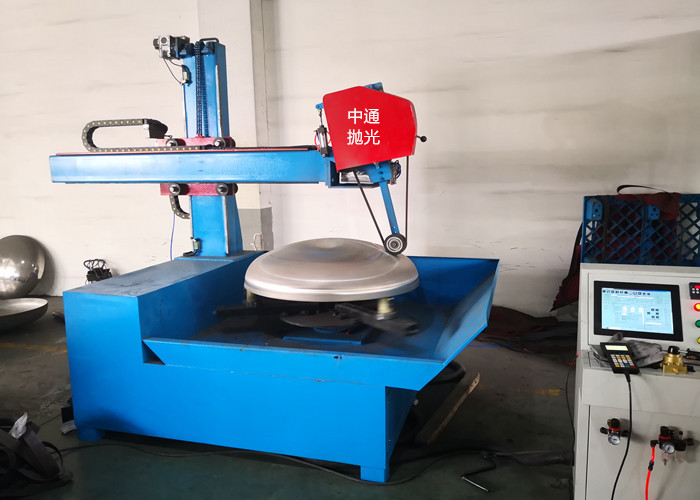

Different polishing machines require polishing personnel to master different techniques. Regarding how to handle workpiece thickness issues with stainless steel mirror polishing machines, the above discussion provides valuable educational guidance.