Company Profile

Company Profile

Hefei Zhongtong Polishing Machinery Co., Ltd. was established by technical personnel from the former Anhui General Machinery Factory under the Ministry of Ordnance Industry. The company specializes in the design, manufacturing, sales, installation of mechanical polishing (grinding) equipment and provides process solutions for polishing (grinding).

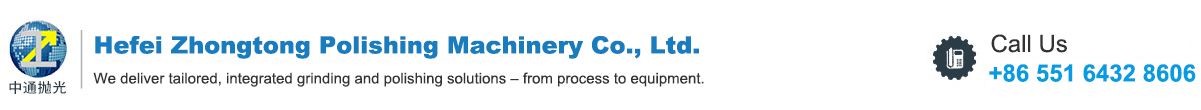

With over ten years in the polishing (grinding) machinery industry, we have consistently adhered to the professional spirit and attitude of the military industry. We cooperate with professional institutions to research, develop, and absorb advanced foreign polishing (grinding) technologies. Market-oriented, we have provided polishing (grinding) machinery (production lines) to over a thousand domestic and foreign enterprises including Baosteel, CRRC, CSIC, China National Nuclear Corporation, AVIC, CNPC, Sinopec, CIMC, Sany Heavy Industry, Dongfeng Motor, JAC Motors, and Heli Forklift. The new generation of fully automatic CNC head polishing machine developed in cooperation with Hefei University of Technology, Hefei General Machinery Research Institute, and the Third Design Institute of the Ministry of Chemical Industry has achieved full automation in head polishing and is widely used in pharmaceutical machinery, food machinery, water treatment equipment, and chemical machinery industries. Based on professional technical research and talent development, and integrating high-quality abrasive tools from international professional companies (3M USA, VSM Germany, Bison Japan), the company has accumulated rich practical experience in metal surface belt grinding and polishing processing technology research and product development, establishing significant professional advantages in the domestic grinding and polishing industry.

The miniaturized head and tank polishing machine has been adopted by Canaan Technology, Jinzhao Technology, Shandong Golden Eagle, Harbin Nano, and other companies in the pharmaceutical machinery, medical, and water treatment equipment industries. It is also widely used in water treatment equipment industries such as non-negative pressure water supply, filter industry, and LNG cylinder industry.

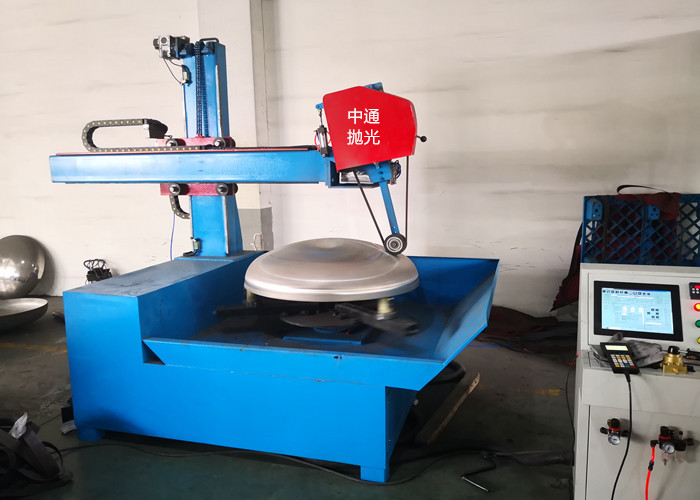

Large-scale head and tank polishing machines are widely used in heavy machinery, such as nuclear power generation equipment, petroleum transmission pipelines, and weld grinding and polishing of large petroleum storage tanks in the chemical industry. Customers include Qinshan Nuclear Power Plant of China National Nuclear Corporation, Formosa Plastics Group, Liaoning Jinxi Chemical Machinery, Nanjing Chemical Machinery, and Taiji Enamel.

Our large surface polishing (grinding) machines are widely used for mirror surface polishing (grinding) of composite stainless steel plates, stainless steel plates, aluminum plates, and titanium plates. The self-developed heavy-duty wide-belt grinding machine has been directly used by customers to replace gantry milling machines for processing large flat plates, fully demonstrating its high efficiency and high-quality surface effects. It has been adopted by Dongfeng Motor, Jiangnan Chemical Industry, North Industries Corporation, and Qiujing Group.

The radiator arc surface and end face grinding (polishing) production line developed for radiator industry users can save 29 workers per shift, with efficiency 80 times that of manual grinding. Centralized dust removal improves the environment, significantly reduces costs, and greatly improves surface quality. Therefore, it has been adopted by the cast iron (aluminum) radiator industry and has obtained relevant patents.

The turntable multi-station grinding (polishing) machine developed for the cast iron pot and stainless steel pot industry fills a market gap, with efficiency 20-30 times that of manual work.

The fork grinding machine developed for Heli Forklift Co., Ltd. is not only widely used in the domestic fork industry but has also been adopted by Italian Bolzoni company and American Cascade company.

The various grinding and polishing production lines developed for stainless steel products such as pots, locks, and hinges are widely used in metal products, hardware electronics, sanitary ware, bathroom fixtures, lighting, plumbing, tableware, kitchenware, chassis, cabinets, furniture, lock industry, automotive, guide columns, piston rods, ball screws, stainless steel vacuum cups, and various other industries. The products feature high quality, consistent surface finish, high efficiency (saving substantial labor costs), and excellent environmental performance.

Since 2009, over 100 polishing (grinding) equipment and production lines have been exported to Southeast Asian countries and the Middle East, including the United States, Australia, India, Thailand, Indonesia, and Saudi Arabia.

Hefei Zhongtong Polishing Machinery Co., Ltd. has become one of the influential enterprises in the development and supply of machine tool equipment in the domestic polishing (grinding) field. Over the past ten years, we have provided nearly a thousand polishing and grinding equipment (production lines) to nearly a thousand customers in various industries at home and abroad. We will continue to adhere to the principle of "Integrity, Professionalism" to create value for customers. Before sales, our professional engineers provide process consultation, solutions, product introduction, recommendation and selection, and pre-sales testing. During sales, we have established comprehensive process control systems including design review, quality control, factory testing, installation and commissioning. After sales, we maintain customer Archives, regularly follow up on product usage, and provide free after-sales service for products.

While continuously improving the quality of conventional products, we will strengthen the development of polishing (grinding) production lines, robot polishing (grinding) products, and intelligent polishing and grinding equipment to create greater value for customers.