Wire polishing machine

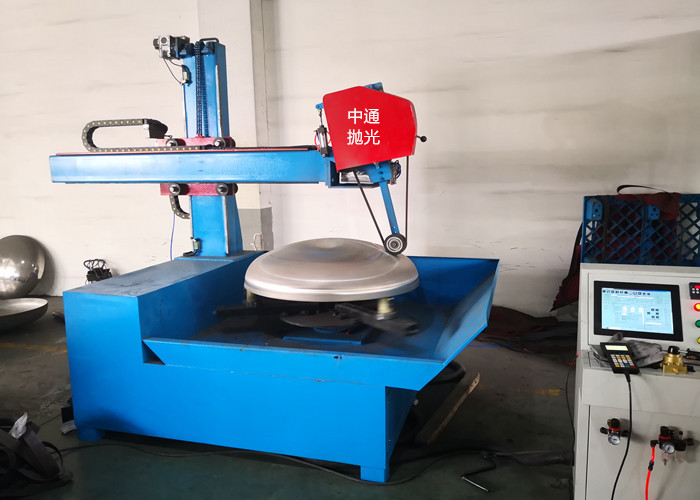

1. Equipment Overview:

This equipment is suitable for surface removal of oxide scale, black skin, defects, and mirror polishing of metal wires such as titanium-nickel alloy wires, superconducting new materials, stainless steel wires, copper and aluminum wires, welding wires, spring steel wires, etc. It replaces pickling with mechanical polishing, saving energy and being environmentally friendly. The equipment is widely used in aviation, aerospace, shipbuilding, military manufacturing, chemical industry, automobile manufacturing, and medical device products industries.

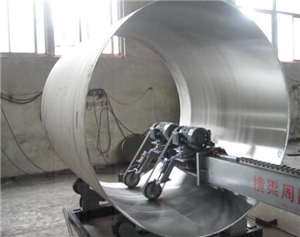

2. Working Principle:

This equipment applies a planetary working principle, using the abrasive belt to revolve around the wire while simultaneously rotating at high speed. The wire passes straight through the middle of the abrasive belt under the action of the unwinding and rewinding systems. The micro-cutting of the abrasive belt removes the oxide scale, black skin, and defects on the metal wire surface. The abrasive belt grit can be selected according to the process requirements for oxide removal and mirror polishing. According to the customer's processing volume requirements, more than two sets of polishing systems can be installed. A dust collector can be configured according to user requirements.

3. Technical Parameters:

Processing range: ¢0.5-¢8mm

Polishing motor power: 2*3KW

Abrasive belt specification: 50*1880mm

Wire feed speed: 18-20m/min

Overall dimensions (mm): 1600*600*1000

- Next: 已经到达最后一个