公司动态

Zhongtong Polishing introduces to you: What is high gloss batch flower?

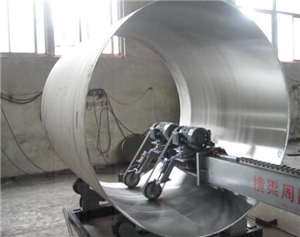

Strictly speaking, high-gloss engraving processing of aluminum signs does not belong to pre-treatment, but to post-processing. High-gloss cut aluminum signs, with their high glossiness and combination of coarse and fine tool marks, utilize the principle of light refraction to greatly enhance decorative effects, and have been very popular in the past two years.

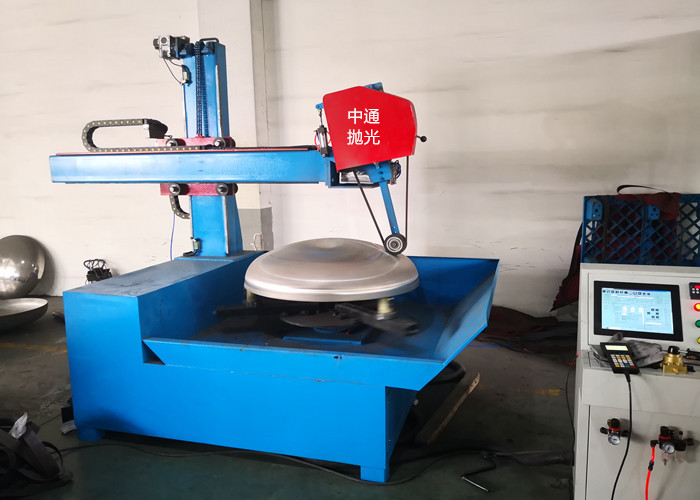

1. High-gloss engraving uses CNC special equipment and diamond tools for rapid cutting, making the surface of aluminum signs and other decorative parts present a high-gloss brushed effect. During the cutting process, heat generation causes an oxide film to form on the surface of the aluminum sign, protecting the processed surface to maintain brightness and achieve a mirror effect for a long time.

2. During processing, the worktable must be able to feed quickly, with tool speed ranging from 7000 to 10000 RPM, and the blade angle is generally about 130°. For special requirements, tools with various angles can be customized.

3. According to reports, the design of the cutting angle on aluminum signs is related to the thickness of the aluminum plate and the size of the corner, generally 45°~30° is appropriate.