公司动态

Stainless Steel Mirror Polishing Processing Methods

Currently, there are two methods to achieve stainless steel mirror polishing: one is chemical polishing, and the other is using a stainless steel polishing machine.

Chemical polishing is a method that relies on the selective dissolution effect of chemical reagents on uneven areas of the sample surface to eliminate grinding marks and achieve etching and leveling. Basic principle of chemical polishing: The electrochemical potentials of various constituent phases on the metal sample surface differ, forming many micro-potentials that cause uneven dissolution in chemical solutions. During the dissolution process, an oxide film forms on the sample surface layer. The protruding parts of the sample surface have thinner mucous membranes, resulting in slower metal dissolution and expansion rates. The polished surface becomes smooth but forms small undulating waves, which cannot achieve ideal requirements. When observed under low and medium magnification microscopes, these small undulations are generally within the vertical resolution capability of the objective lens, and clear microstructures can still be observed.

Chemical polishing procedure: 1. Sample preparation: Clean the sample after fine grinding. 2. Prepare chemical polishing solution. Chemical polishing solutions should be prepared in beakers. Select the chemical polishing solution formula according to the sample material, use distilled water for preparation, and use chemically pure reagents. Some reagents that are not easily soluble in water require heating to dissolve. Hydrogen peroxide and hydrofluoric acid are highly corrosive, so safety precautions must be taken during preparation. After use, the metal ion content in the chemical polishing solution increases, weakening the polishing effect. If slow action and reduced bubbling are observed, replace with new solution. 3. Immerse the sample into the polishing solution using bamboo or wooden clamps, stir while immersed, and remove periodically for observation until polishing requirements are met. 4. After chemical polishing, immediately clean and blow-dry the sample. The disadvantage of chemical polishing is environmental pollution.

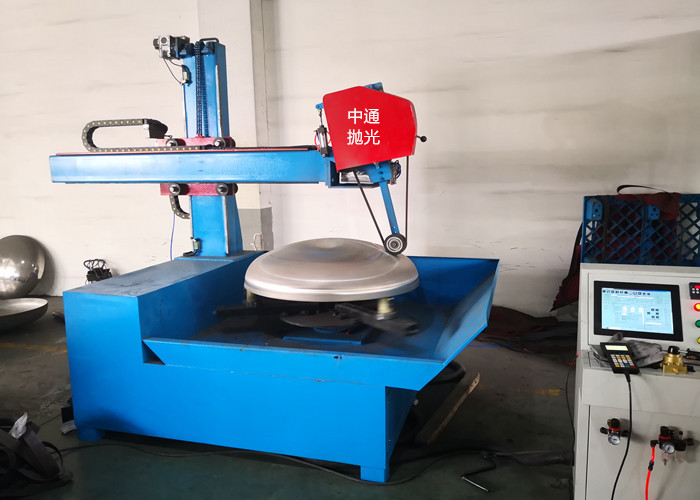

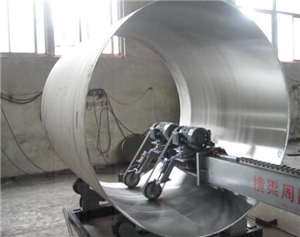

Principle of stainless steel polishing machine: The engine drives the grinding disc to rotate, creating friction with the workpiece that rotates on the disc. This friction generates cutting force to grind down uneven areas of the workpiece surface, achieving the polishing purpose.

Characteristics of flat polishing machine: 1. Uses intermittent automatic spraying device with adjustable spray intervals. 2. Workpiece pressure application uses air cylinder pressure method with adjustable pressure; after polishing, the workpiece surface has high brightness, no scratches, no material patterns, no pitting, no edge collapse, and high flatness. After polishing, the workpiece surface roughness can reach Ra0.0002; flatness can be controlled within ±0.002mm range. 3. Uses PLC programming control system with touch screen operation panel; grinding disc speed and timing can be directly input on the touch screen. 4. Only suitable for polishing flat surfaces of workpieces.

After using stainless steel polishing machine, the surface smoothness can reach about 0.002mm, which chemical polishing cannot achieve; therefore, stainless steel mirror polishing generally chooses stainless steel polishing machines. The polishing machine can remove scratches, spots, and edge collapse phenomena on the stainless steel workpiece surface, making the workpiece surface bright, smooth, and achieving mirror effects. Generally, equipment manufacturers will first help customers with samples, and only after confirming the product can be produced will customers consider purchasing the equipment. This is why many friends choose machine processing.

- Next: 已经到达最后一张